The 2020+ Ford Explorer ST & 3.0L Ecoboost SUV’s are amazing vehicles, packed full of performance with lots of torque for towing. Unfortunately the “single-bolt” OE differential support can be prone to failure under load when towing or during hard launches when racing.

If the rear axle mounting bolts snap or fracture, the housing becomes partly dislodged from the chassis. This can cause it to make noise and create vibrations. It can also lead to the half-shafts pulling away and becoming dislodged, causing severe damage to your vehicles drivetrain.

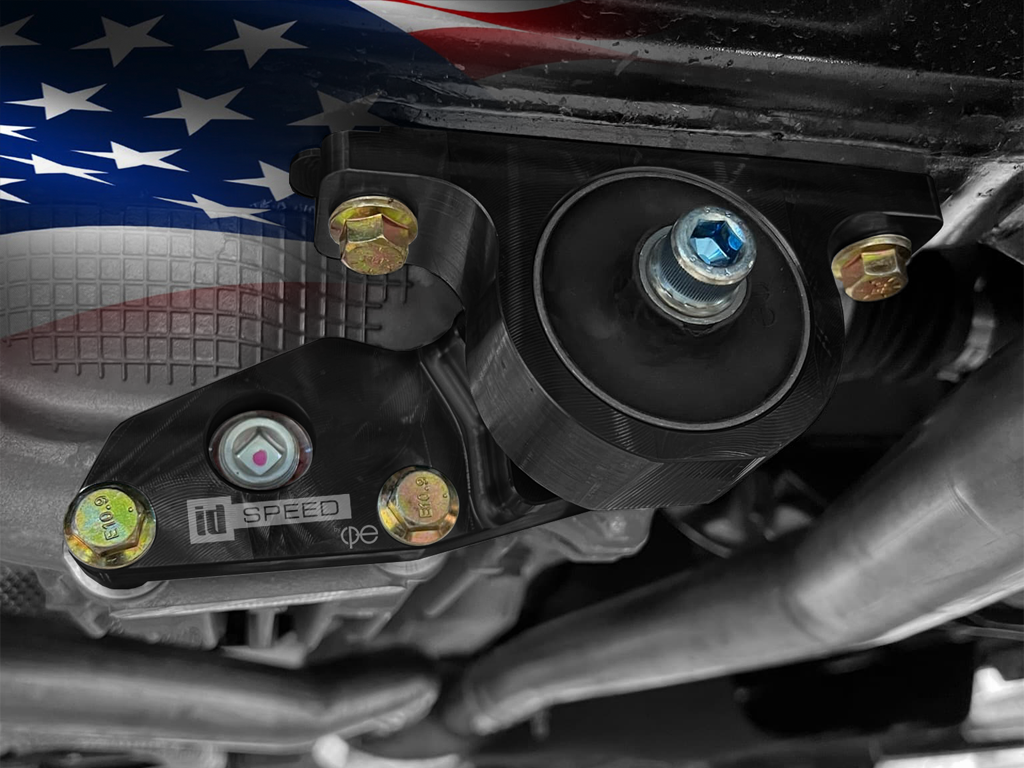

Fear not. ID Speed Shop has the solution with our 2020+ Ford Explorer Rear Differential Reinforcement kit with fully integrated stabilization system. Our brace FULLY reinforces your Explorer differential case, while improving your vehicles traction!

Whether you're just driving daily on the street, at the track or towing your boat, you can be confident knowing your differential is supported and less likely to fail.

Manufactured from lightweight Military Grade 6061 T6 Billet Aluminum, the ID Speed 2020+ Explorer Differential Brace was designed to handle the extreme forces applied during towing & hard launches.

The ID Speed 2020+ Explorer Differential Brace features:

- 4 mounting points to the rear differential for maximum support & stabilization.

- Superior EPDM Bushing to reduce vibration & maintain structural integrity.

- Fluid drain hole access without having to remove the brace

- Zinc Coated Grade 12.9 / Grade 8 bolts & Black Anodized coating for maximum corrosion resistance.

Drain Hole Access

Fluid drain hole access without having to remove the brace

4 Mounting Points with Grade 12.9 Hardware

4 mounting points to the rear differential for maximum support & stabilization with Grade 12.9 Zinc plated bolts to prevent corrosion.

Superior EPDM Bushing

Superior EPDM Bushing to reduce vibration & maintain structural integrity.

Unlike nearly all other mounts and brackets from other manufacturers, we use EPDM for our bushings. This provides much more vibration resistance when compared to polyurethane. This material is also extremely resilient and is able to stretch and even develop small cracks without affecting its structural integrity. EPDM is much more expensive to produce, but it is a far superior bushing material.

Our metal inserts are physically pressed into our EPDM bushings. This allows the bushing material and the metal to have a perfect connection without any gap. Other manufacturers cut their material out to fit, leaving small tolerances where the metal can still vibrate. Our construction allows the EDPM to absorb the vibrations and allows the metal inserts to smoothly move with the EDPM.

WARNING : Cancer and Reproductive Harm - www.P65Warnings.ca.gov.

WARNING : Cancer and Reproductive Harm - www.P65Warnings.ca.gov.